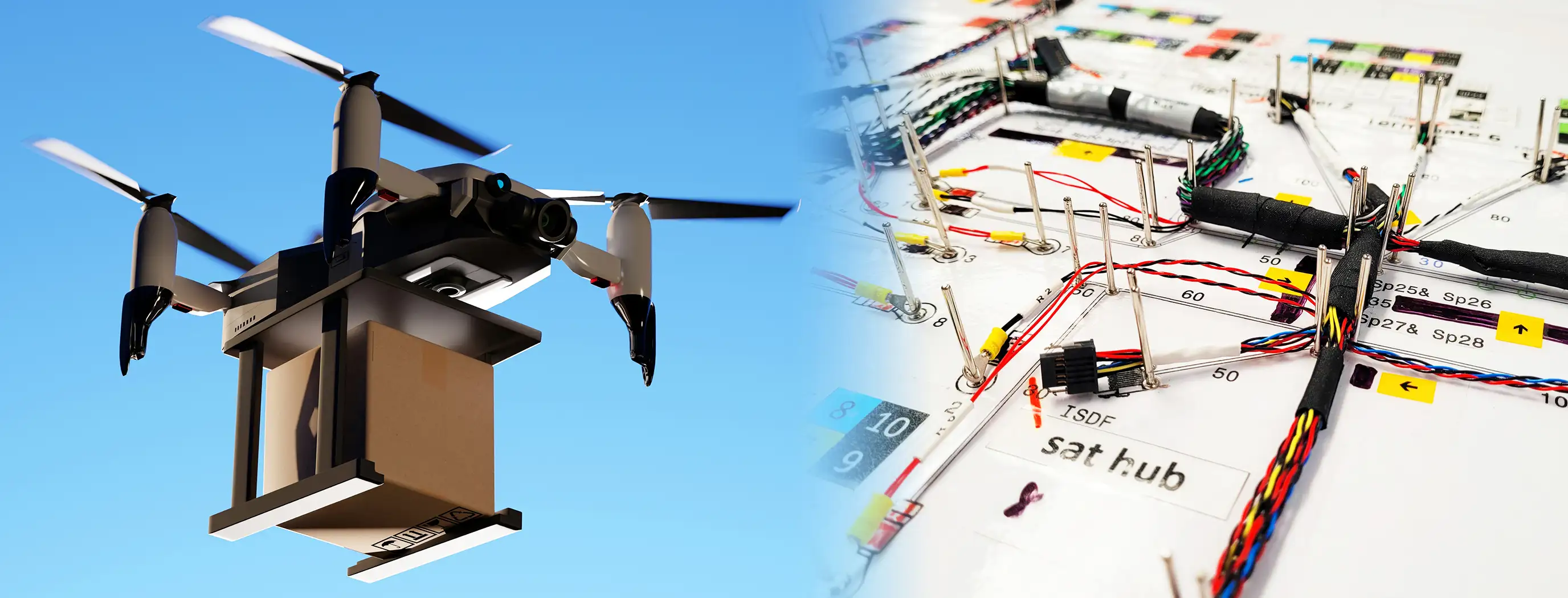

Enhancing Delivery Drones for Healthcare Logistics

Our customer was developing a fleet of UAVs for the distribution of medical supplies.

However, they didn't have any prior cable assembly knowledge, and all of their designs were in spreadsheets. They needed product and engineering support from a supplier who could also offer complete supply-chain traceability on all builds, as well as 100% test and inspection.

The Solution

We converted the customer's files into production-ready, technical drawings. We also improved their schematics and designs, removing 50% of splices from their cable looms, resulting in an impressive weight-saving. Fullscale loom boards were built for prototype builds, and we then broke these up into 42 sub-assemblies for full production.

Manufacturing was split across our sites in the UK and Romania, delivering lean and automated production processes. Every production run was given a unique QR code, which provided full material and operator traceability.

Cost-Efficiencies

Through BOM analysis, we enhanced designs and removed unnecessary components, which reduced costs. By automating the build process, we also increased the overall efficiency of production.

Time Saving

By combining resources across our UK and Romania sites, we automated the manufacturing and implemented our Core Material Strategy, which led to reduced build costs.

Business Advantage

In addition to supporting the customer with cable engineering expertise and fully-traceable manufacturing, we also offered guidance on the required safety-critical approvals.